Current Challenges

・Because waste plastics and discarded tires were used as fuel, dust and malignant gases were produced in the "incineration process". Dust could be collected with a bag filter, but malignant gas removal was difficult.

・Because the gas had a temperature of 70 C and was acidic in nature, concerns about corrosion arose.

Installation Conditions

・Safely absorb acidic gases

ACO's Proposal

1.Combination of Bag Filter and Wet Scrubber

•Preliminary dust collection with a bag filter, followed by absorption of acidic gases using a "Wet Scrubber" designed for gas absorption.

2.Cylindrical Design for Strength and Corrosion Resistance

•The entire structure will be cylindrical to enhance strength.

•Fabrication using corrosion-resistant FRP (Fiberglass Reinforced Plastic) to withstand acidity.

3.Optimal Utilization of Wastewater Treatment Facilities

•Taking advantage of the existing wastewater treatment facilities, the contaminated water inside the Wet Scrubber will be discharged without neutralization, reducing maintenance efforts.

4.Equipped with Inspection Ports for Internal Cleaning and Maintenance

•Installation of inspection ports to facilitate internal cleaning and maintenance.

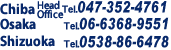

Inquiries

A sales engineer will directly address any of your questions. For inquiries by email, please complete the form below