High performance Wet Dust Collector

Dust collection, gas absorption,

odor removal problems solved!

No clogging! Stable air volume!

High Performance

Unbelievable Dust Collection Efficiency

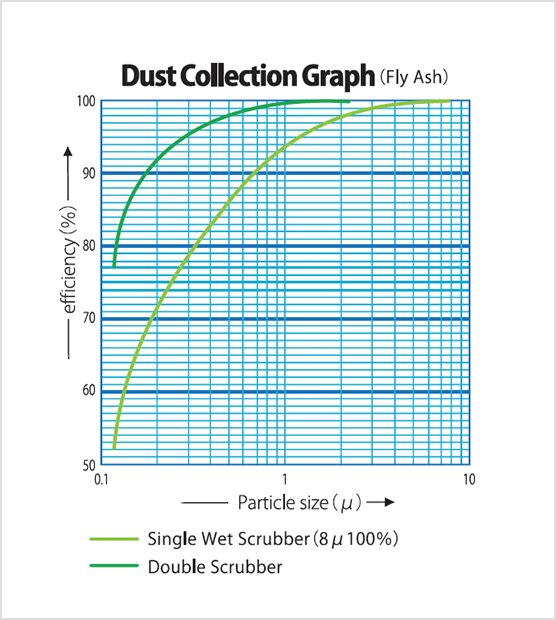

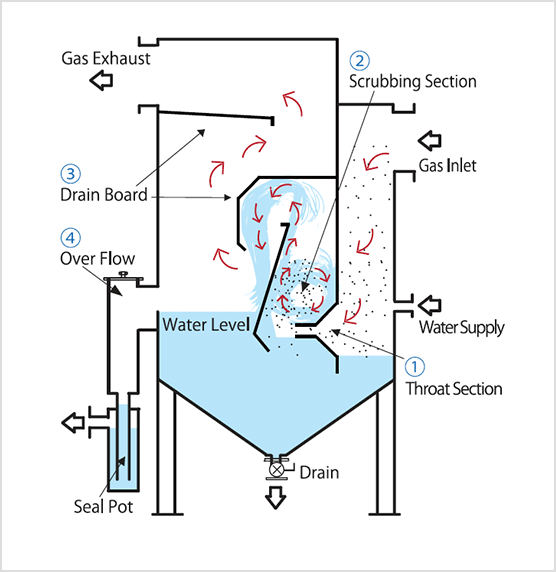

Excellent dust collection allows extremely efficient Dust /Gas treatment. By adding a second scrubbing section to the standard wet scrubber (1.0micron 93% collection), a super-efficient “Double Scrubber”(1.0micron 99% collection) can meet any dust collection needs.

Wet Scrubber; Principle and DesignWho uses Aco scrubbers?

- Companies requiring dust removal, gas treatment and odor removal.

- Companies wishing to clean heavy dust work areas

Low Cost

Unique level Production Technology

Aco scrubbers make low-cost operation a reality through unique production technology and simple design.In comparison to packed tower type apparatus, Aco scrubbers are easy to maintain therefore lower maintenance costs after installation can be expected.

To see the difference between Packed Tower Type and Wet Scrubber click here.Who uses Aco scrubbers?

- Factories which want to increase profitability by improving dust removal efficiency

- Factories which want to reduce costs incurred by filter clogging and have better operating stability

Space-Saving

Custom-made therefore perfect for your needs

All Aco products are custom-made to meet any requirement you have concerning performance, installation space, gasses being handled etc.

All products are built using stainless steel (SUS304, 316L) or FRP.

Who uses Aco scrubbers?

- A high-performance dust collector was needed for a factory with limited space.

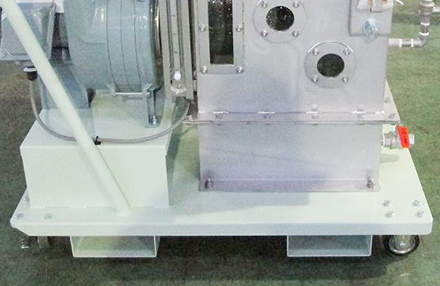

- A compact, movable type dust collector was needed.

Case Study: Welding Factory

Because of its performance and movability, a scrubber was introduced to collect spatter and fumes when plasma cutting. Caster equipped scrubbers for easy moving are available.

High-Safety

Explosion・Fire Prevention

Since the scrubber uses water, there is no chance of fire or explosion even when gasses which contain sparks or flaming materials are handled during cutting or welding operations. Furthermore, there is no danger of dust explosions ignited by static electricity.

See fire prevention experiment hereWho uses Aco scrubbers?

- Factories which experienced fires when using electric dust collectors and bag filters

- Factories where flammable metal dusts are collected

Case Study:Metal Processing Company

Metals were being polished with a belt sander and sparks in the bag filter was causing fires to occur frequently.An Aco wet scrubber was introduced to address the problem.

Fires no longer occur and a safe working environment now exists.